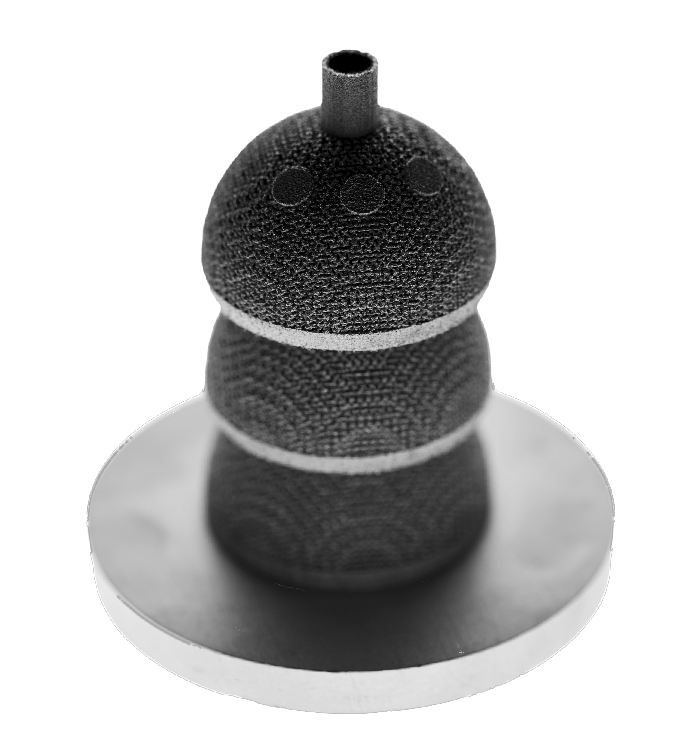

As the global population becomes older and healthier, the need for improved efficiency in healthcare increases, driving demand for advanced products with enhanced lifetime and comfort. Titanium orthopedic implants is one application where additive manufacturing (AM) is transforming the MedTech industry.

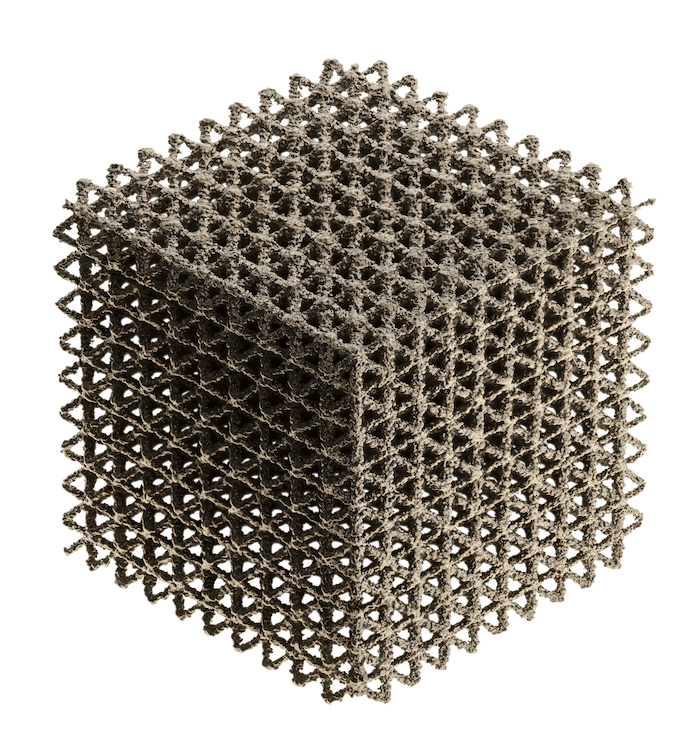

AM enables the creation of implants with intricate geometries and porous structures, leading to lighter implants with improved bone ingrowth, superior fit and function, less complications, and faster recovery times.