As global warming accelerates and energy demand rises, driven by electrification and the rapid advancement of AI, the need for sustainable, fossil-free energy solutions has become more urgent than ever.

Energy

Clean energy generated by innovative energy sources such as fusion or gas turbines has the potential to solve this problem, and additive manufacturing plays an important role in this development.

The value additive manufacturing brings to the energy industry

Shorten time-to-market

Allows for rapid prototyping and design iterations for evolving development.

Innovative manufacturing

Enables the manufacturing of complex designs and materials that withstand harsh operating environments.

Distributed manufacturing

Enable full control of the manufacturing process from material to functional part. The part is manufactured where the part is needed.

Fusion energy

Within fusion, Freemelt’s E-PBF (Electron Beam Powder Bed Fusion) technology offers significant advantages by enabling the production of critical tungsten plasma-facing components capable of withstanding the extreme heat and neutron radiation in fusion reactors. Freemelt’s superior technology and unique machine design print pure tungsten parts in a high-vacuum environment, reducing oxygen and allowing for precise control of material properties and geometries. This opens the door to new designs and faster prototyping for tungsten fusion components.

The value Freemelt’s E-PBF technology brings to the fusion energy industry

High-temperature, high-power process

High-beam power and a process temperature above 1200°C ensure superior strength, durability, and fully dense tungsten parts suitable for demanding fusion reactor environments

Process under vacuum

The ultra-clean vacuum environment prevents oxygen contamination and purifies tungsten during processing, achieving oxygen levels as low as single ppm, enabling superior material quality.

Unique spot melting technology

Enable superior heat management during printing, tailoring tungsten’s microstructure and material properties, critical for fusion reactors that require parts with controlled grain orientation.

Push-feed powder delivery system

Enable the use of cost-efficient irregular powders and expanded supply chains.

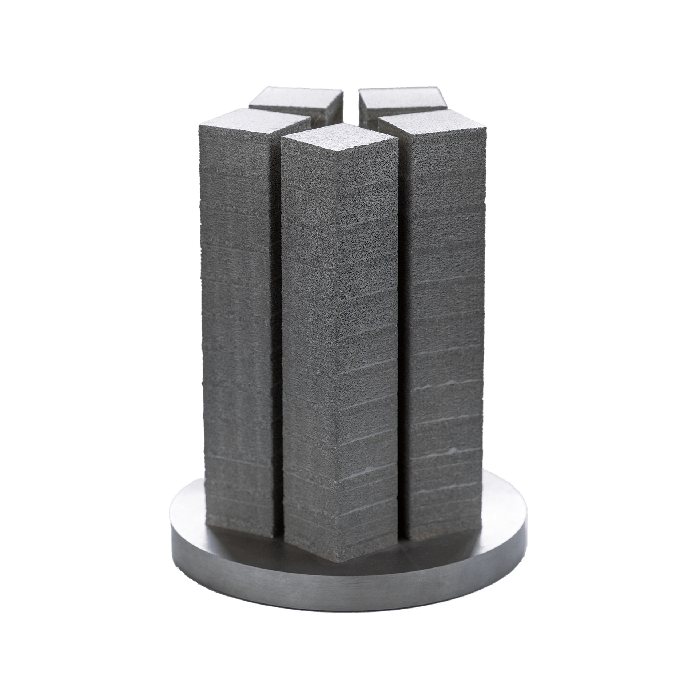

Fusion energy applications printed in Freemelt machines

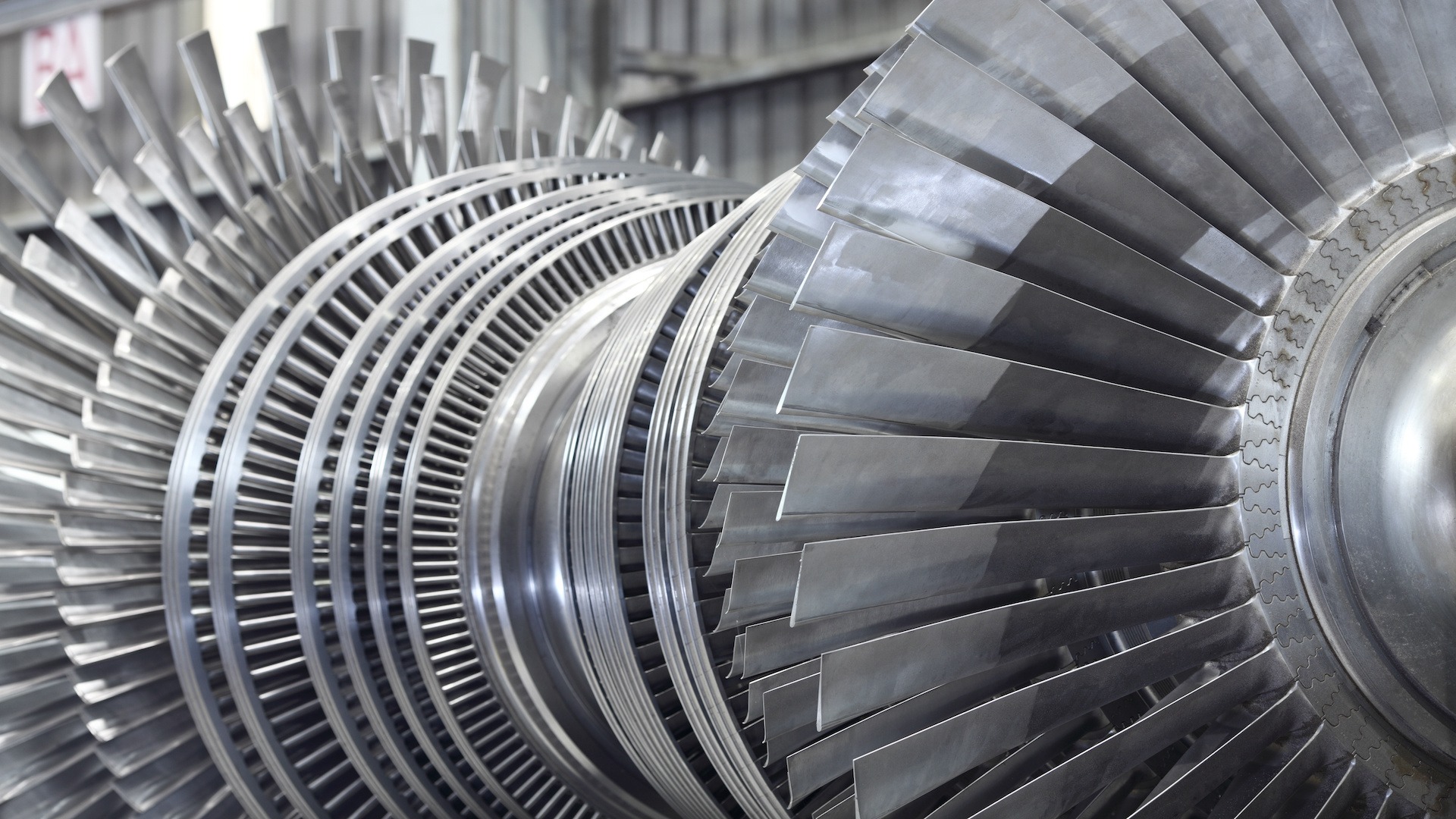

Gas turbine energy

Freemelt’s E-PBF technology offers an efficient solution for manufacturing turbine blades for industrial gas turbines, using advanced materials such as superalloys and titanium aluminides, materials that withstand harsh operating environments. Operating under vacuum minimizes oxygen pick-up and the risk of contamination, which extends powder life and enhances material properties. Freemelt’s technology, combined with a high-temperature process, reduces residual stress and enables the manufacturing of long turbine blades due to the height of the build chamber, maximizing build tank utilization and increasing overall productivity.

The value Freemelt’s E-PBF technology brings to the gas turbine industry

Process under vacuum

Operating in a vacuum minimizes oxygen pick-up and reduces the risk of contamination, enhancing material integrity and extending powder life for longer production cycles.

High-temperature, high-power process

The integration of a high-temperature process reduces residual stress, ensuring parts retain their strength and durability over time.

Optimized machine design

The height of the build chamber allows for greater flexibility in part size and shape, further enhancing the efficiency of the overall production process.

Freemelt – Your partner in sustainable energy development

As the energy sector evolves, driven by the push for fossil-free energy, Freemelt’s advanced E-PBF technology plays a vital role in supporting this transformation. With our unique e¯MELT® machine design, we offer superior solutions for producing high-quality, heat- and radiation-resistant components for the demanding environments inside fusion reactors and gas turbines.

Ready to take your manufacturing to the next level – Freemelt is your partner from initial material qualification to application development and seamless transfer into full-scale serial production. Contact us today to explore how Freemelt’s E-PBF technology can enhance your production capabilities

Read more

Elevating tungsten manufacturing, six reasons to use e¯MELT®

Rediscovering Titanium: New ways to make old thing

Freemelt has established collaborations with UKAEA, Oxford Sigma, Fusion for Energy, and other industrial companies on fusion energy applications. Read more here:

Contact us